Medical Machinery

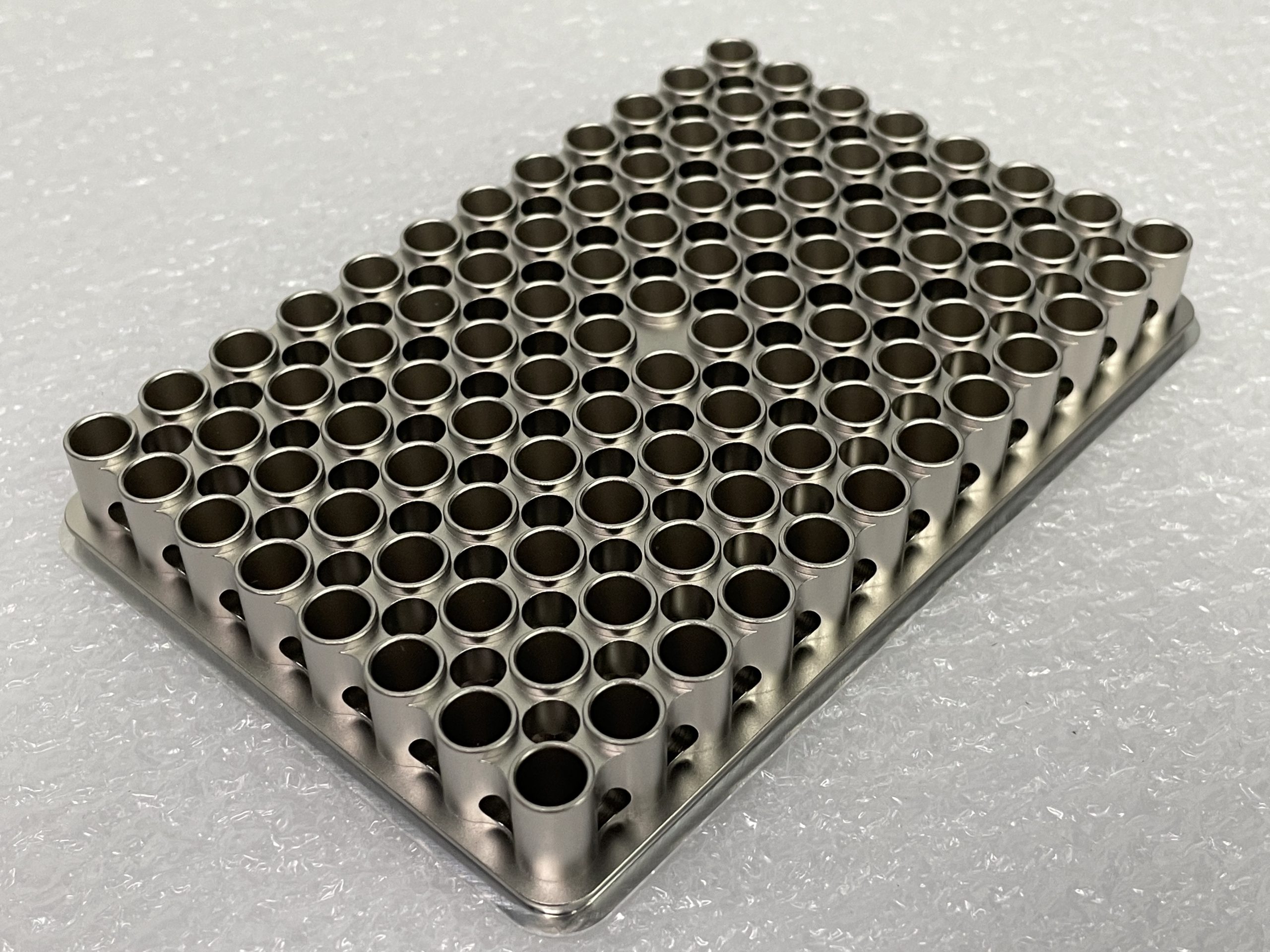

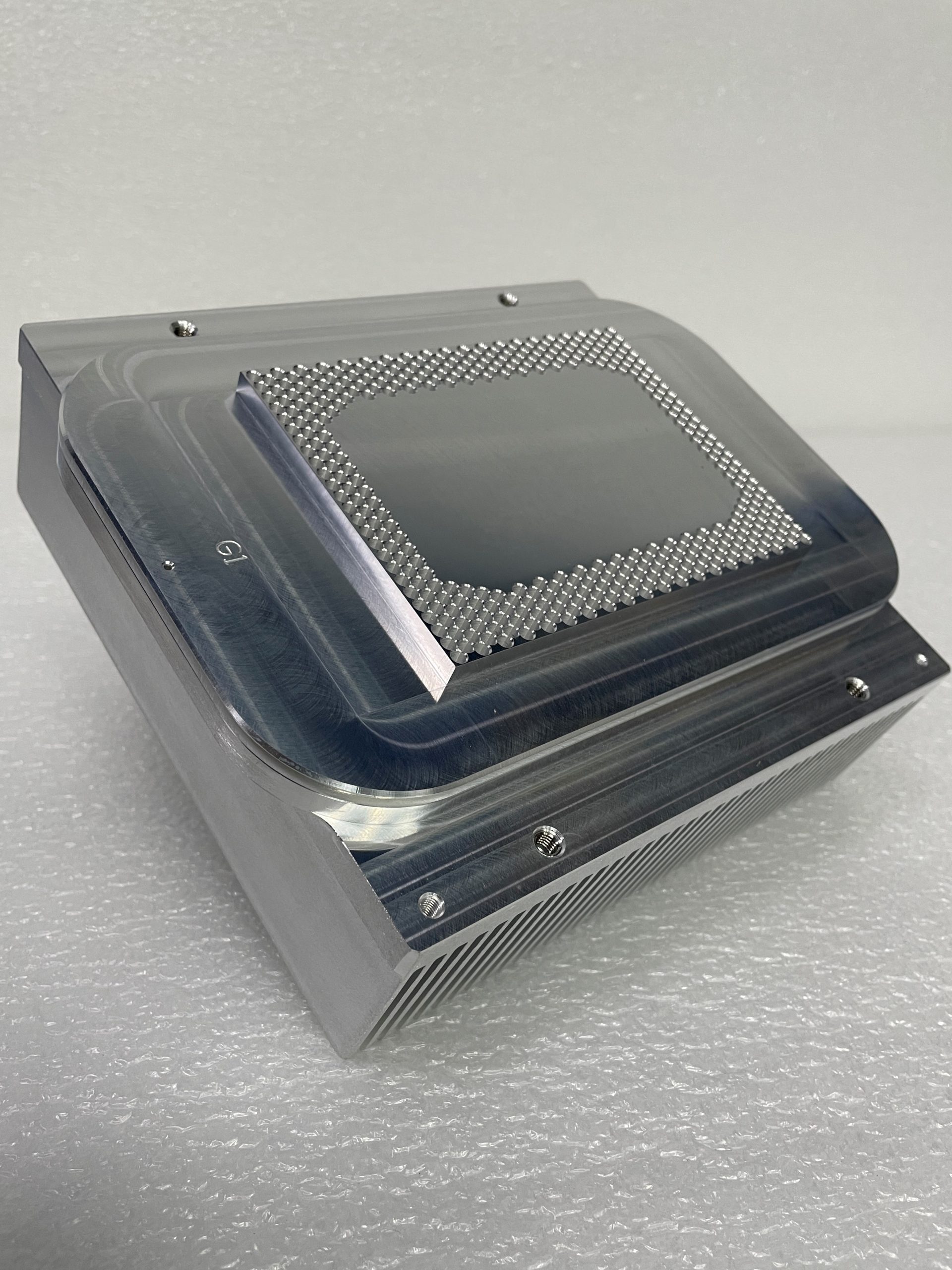

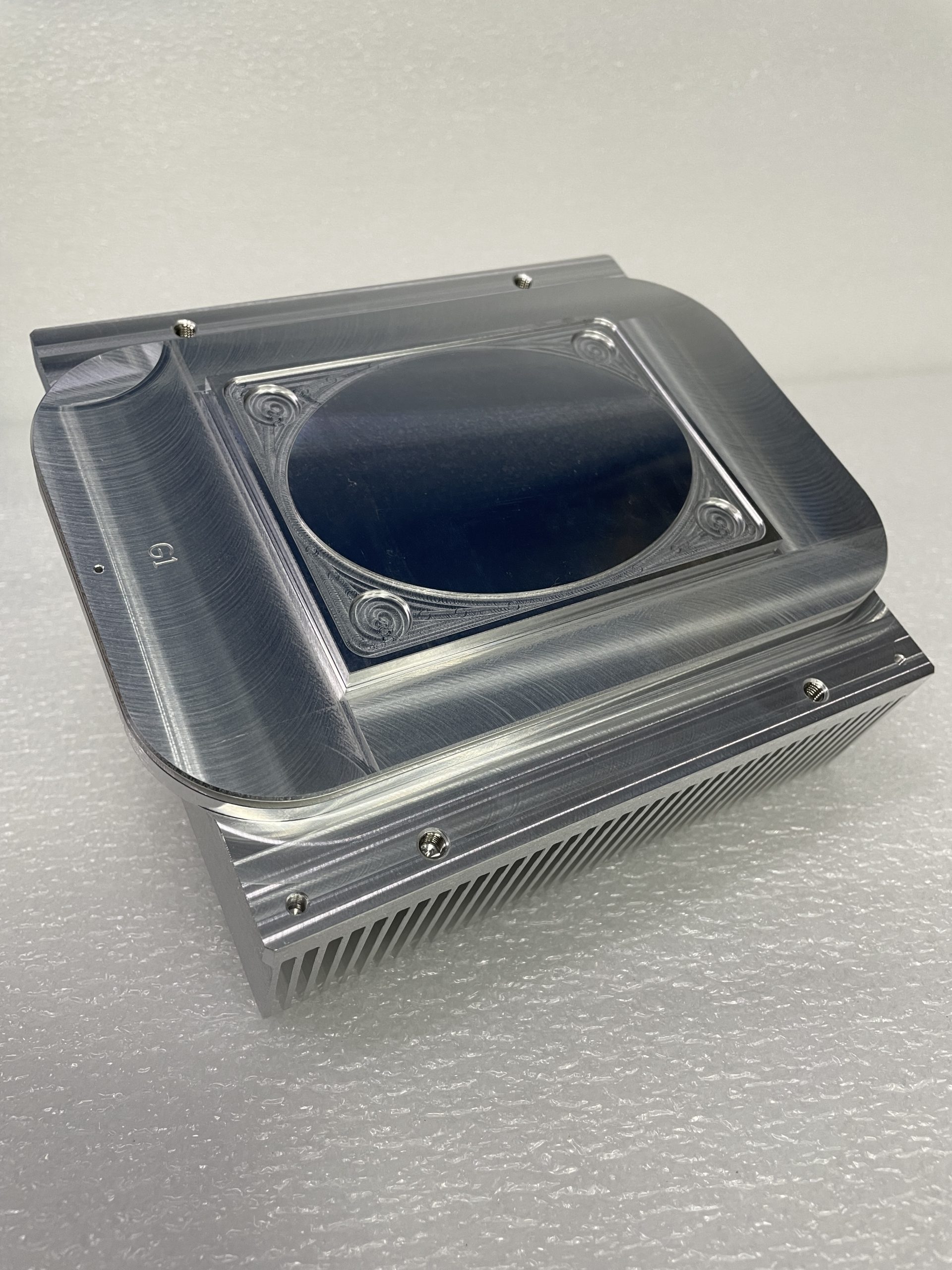

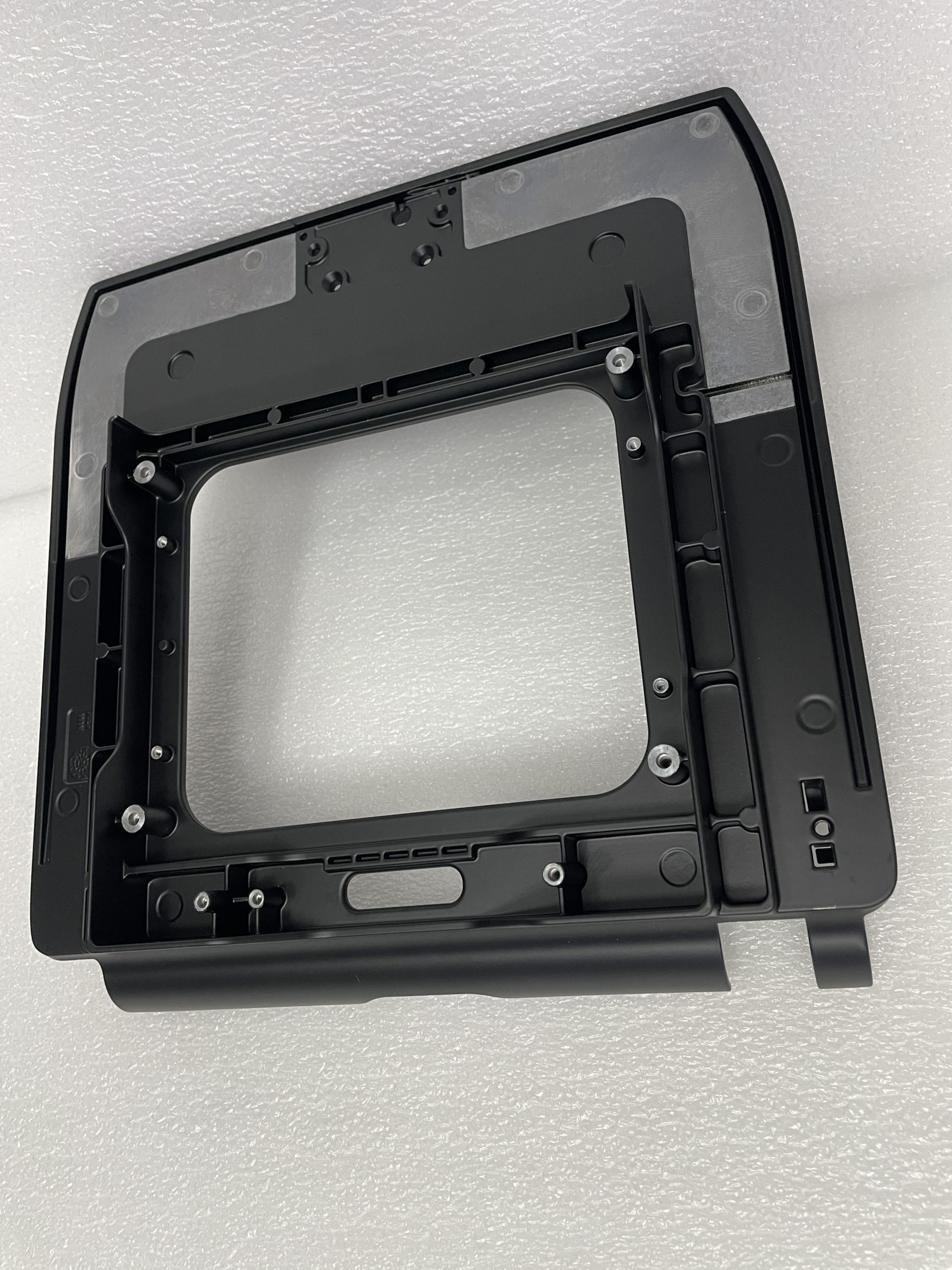

Medical industry products and parts require the manufacturing process chosen to have the ability to meet tight tolerance limits necessary for proper function. Dimensions of features to be created are often at a micron length scale. Surface finish is an important consideration for medical parts, especially those that need to be implanted in the body. CNC machining offers a much better surface finish as compared to other processes such as casting and manual machining.

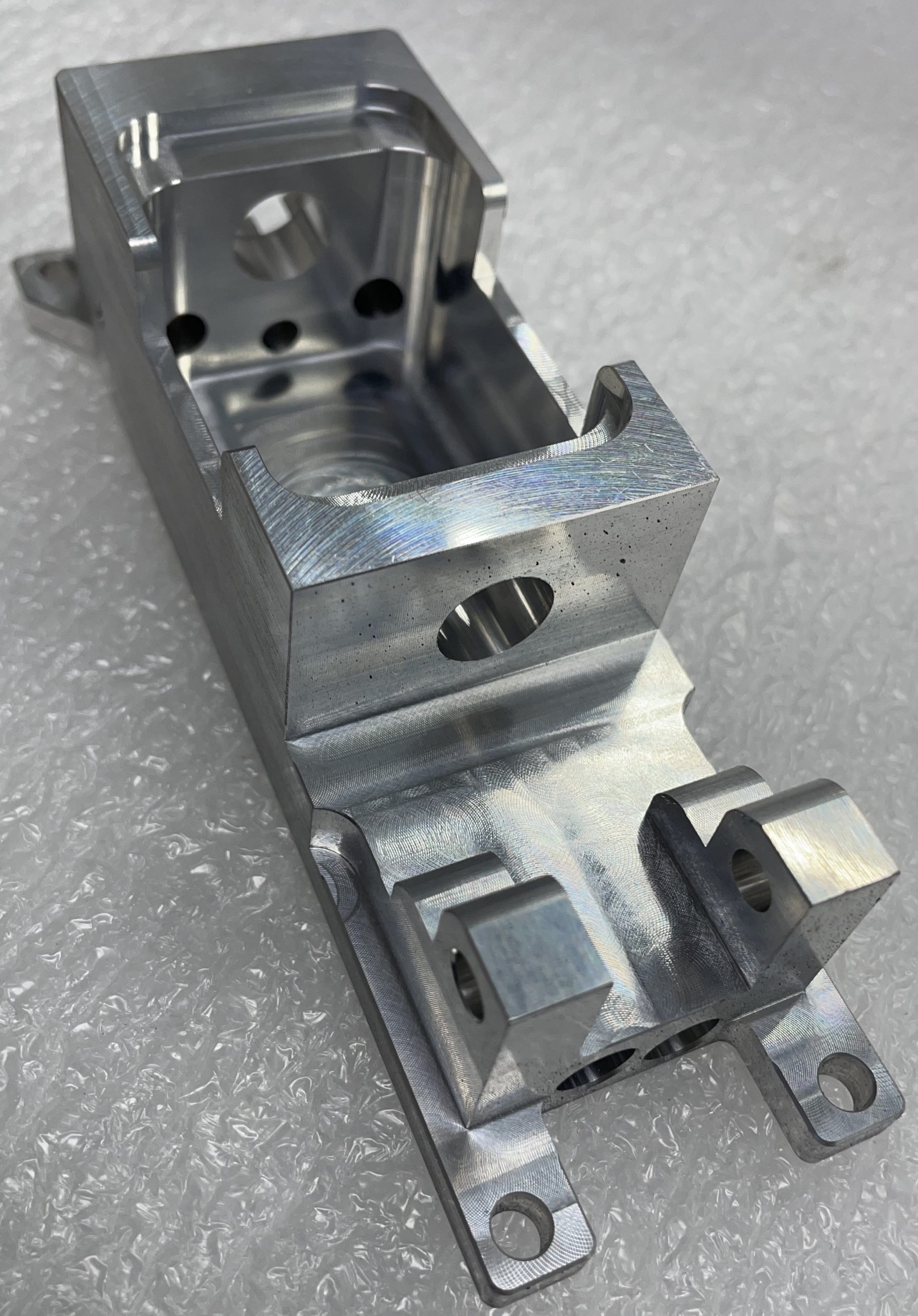

It is necessary to choose a machine shop for medical component manufacturing that meets all of the required standards in addition to possessing the required technology and skills. Meeting internationally recognized quality standards such as ISO 9001:2015 and ISO 13485, an expanded version of ISO 9001:2015, intended to be used by the medical industry is important. Apart from standards and certifications, in terms of ability to meet requirements, it is ideal to have the machine shop is equipped with 4-axis and 5-axis machining capabilities for the creation of complex geometries, which are often present in medical parts. The availability of multi axis machine center facilities greatly adds to the precision machining capabilities for high mix low volumes requirement.

Our ethic of maintaining the highest quality CNC Machined Semiconductor Components does not only pertain to our processes and products, it’s a part of our culture. We know how important fast turn-around times are for high volume and high-value manufacturers to minimize equipment downtime. We will work with our clientele to optimize the performance of their CNC Machined components.